Welcome to the Mevisto Blog

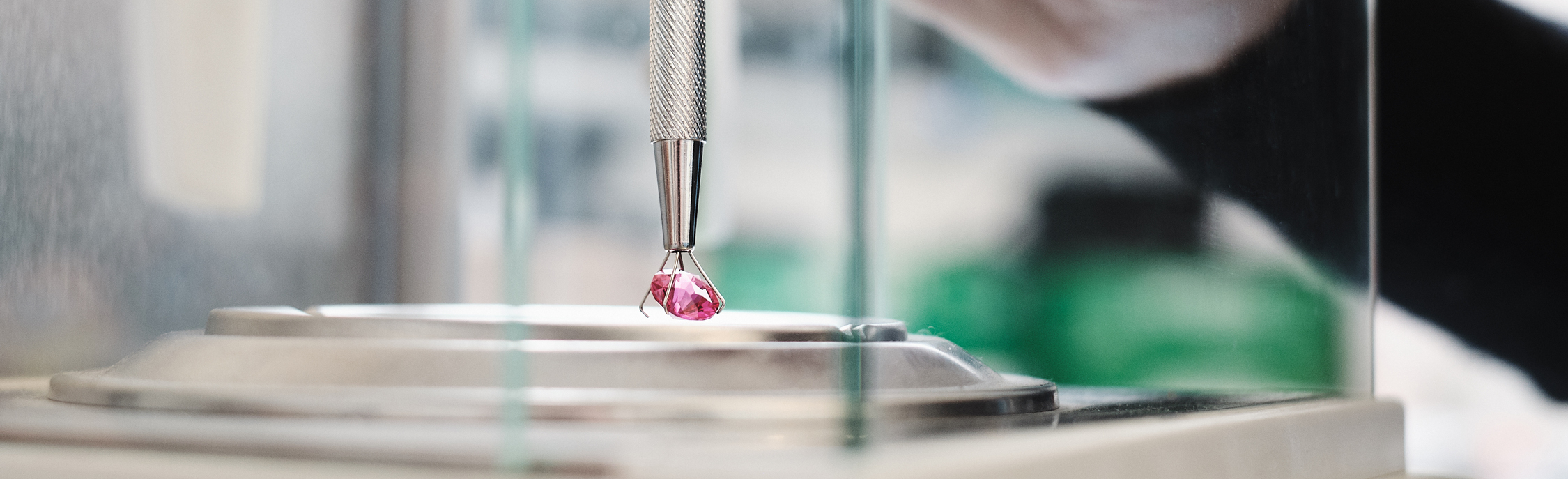

Welcome to the Mevisto Blog! Immerse yourself in the enchanting world of our personalized gemstones and jewelry. Here, we share touching stories, inspiring insights, and the magic that surrounds our unique creations. Let yourself be captivated by the beauty and emotion of our products and discover how Mevisto makes your special moments unforgettable.

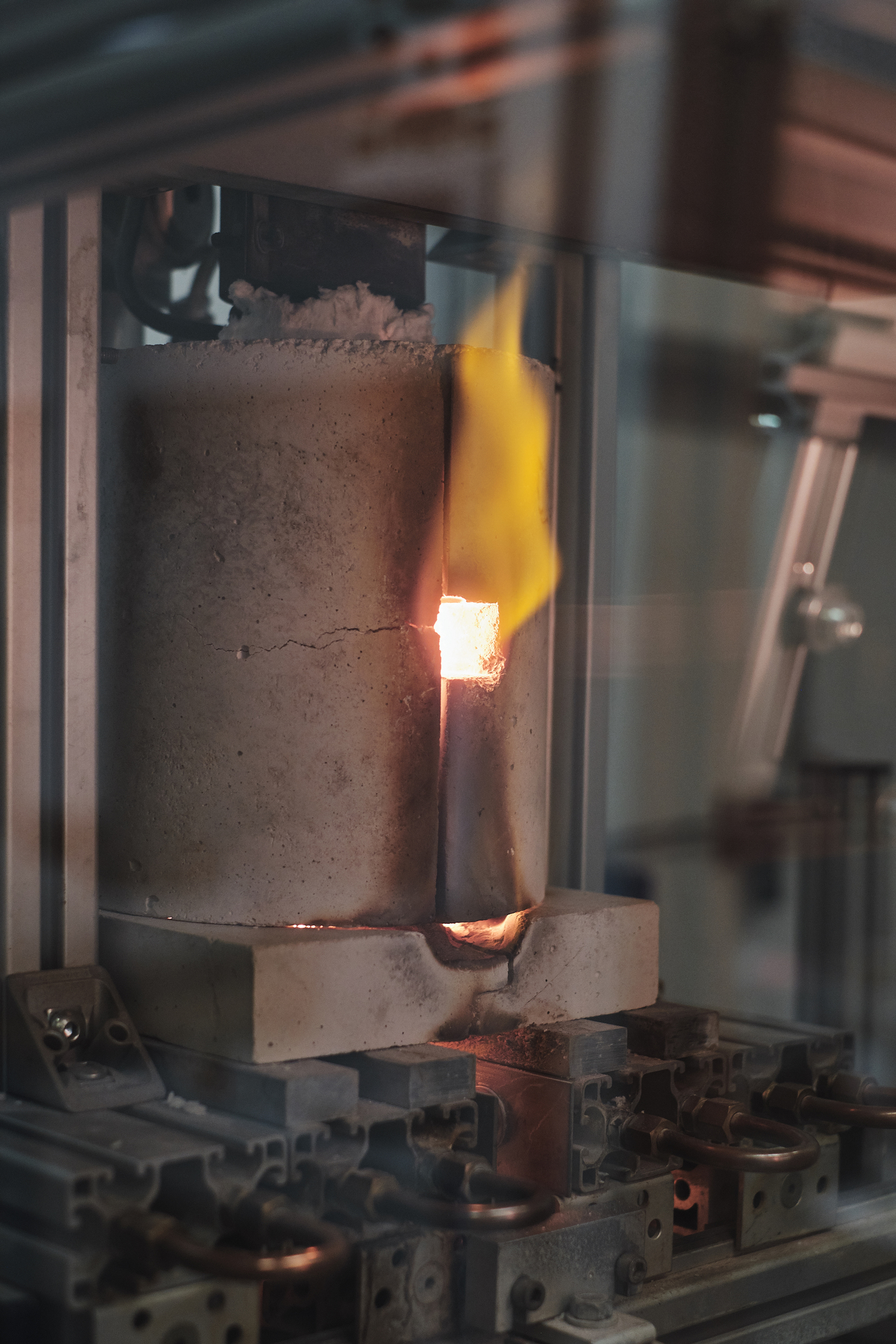

On our blog, you'll find exciting articles about the latest jewelry trends, exclusive collections, and the fascinating processes behind crafting our unique gemstones. Join us on a journey through the stories of our customers who infuse their special memories into our jewelry pieces. Learn more about the significance and symbolism of gemstones and get inspired to create your own unforgettable moments.

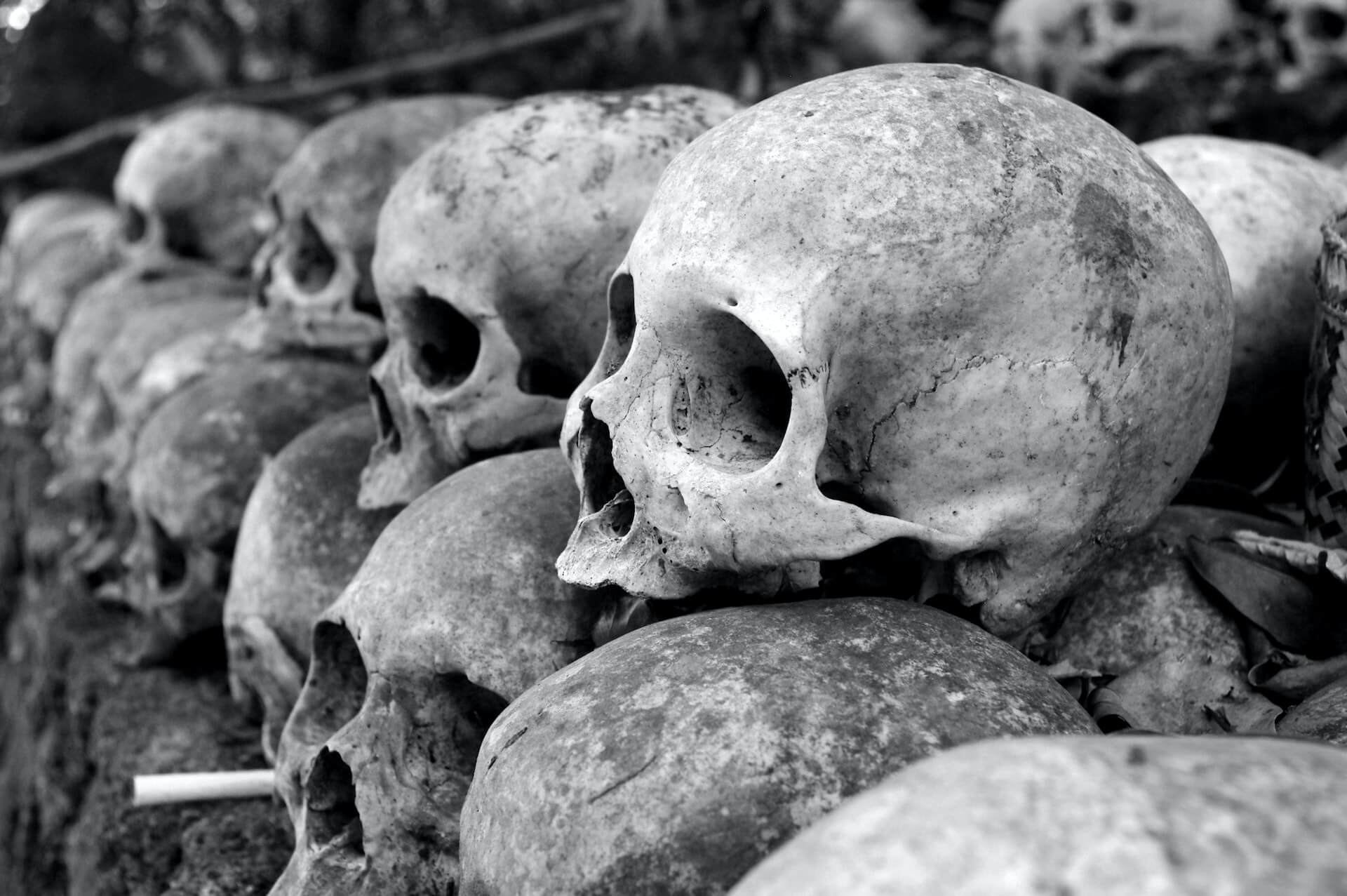

Grieving for a deceased pet: Claudia Kolb's story about “Mucki” ...

Letting go of grief or holding on to the deceased?

Mourning the deceased dog: Pascal talks about his Kurti ...

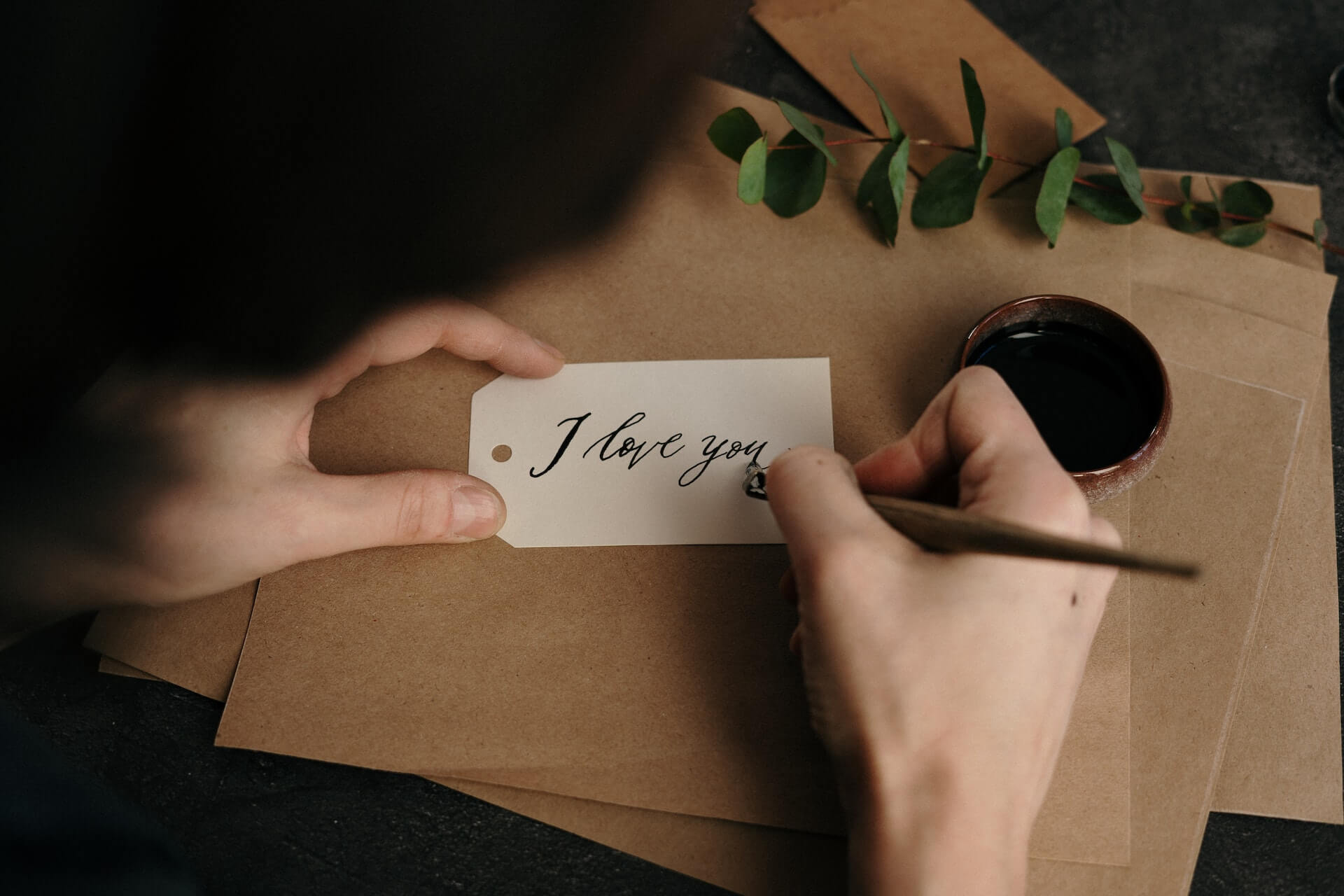

Love in the heart, love in the gemstone

What types of love are there and what characterizes them?

How can you determine your birthstone?